Optimizing Oil Separator Efficiency Through Real-Time Monitoring with Leakwise

In the world of environmental monitoring, precision and real-time data are paramount. When it comes to oil separators, ensuring optimal efficiency isn’t just about meeting regulatory requirements; it’s about protecting our environment and maximizing resource recovery. That’s where Leakwise comes into the picture, providing cutting-edge solutions for real-time monitoring that can transform how we manage oil separation processes.

Leakwise, a company with a rich history dating back to 1990, has been at the forefront of developing innovative technologies for environmental applications. Originally a spin-off from Agar Corporation Inc., Leakwise leverages the power of Electromagnetic Energy Absorption to create highly effective, floating sensor-based systems. This technology allows for the precise and continuous monitoring of oil layers, providing invaluable data for optimizing oil separator performance.

My own experience with Leakwise’s technology has been nothing short of transformative. In a previous project involving a large industrial wastewater treatment plant, we struggled with inconsistent oil separation. The traditional methods we were using – manual checks and periodic lab analysis – were simply not providing the real-time insights needed to fine-tune the process. After implementing Leakwise’s monitoring system, we gained immediate visibility into the oil layer thickness and composition within the separator. This allowed us to make data-driven adjustments to flow rates, chemical treatments, and skimming schedules, resulting in a significant improvement in separation efficiency.

The Importance of Real-Time Monitoring

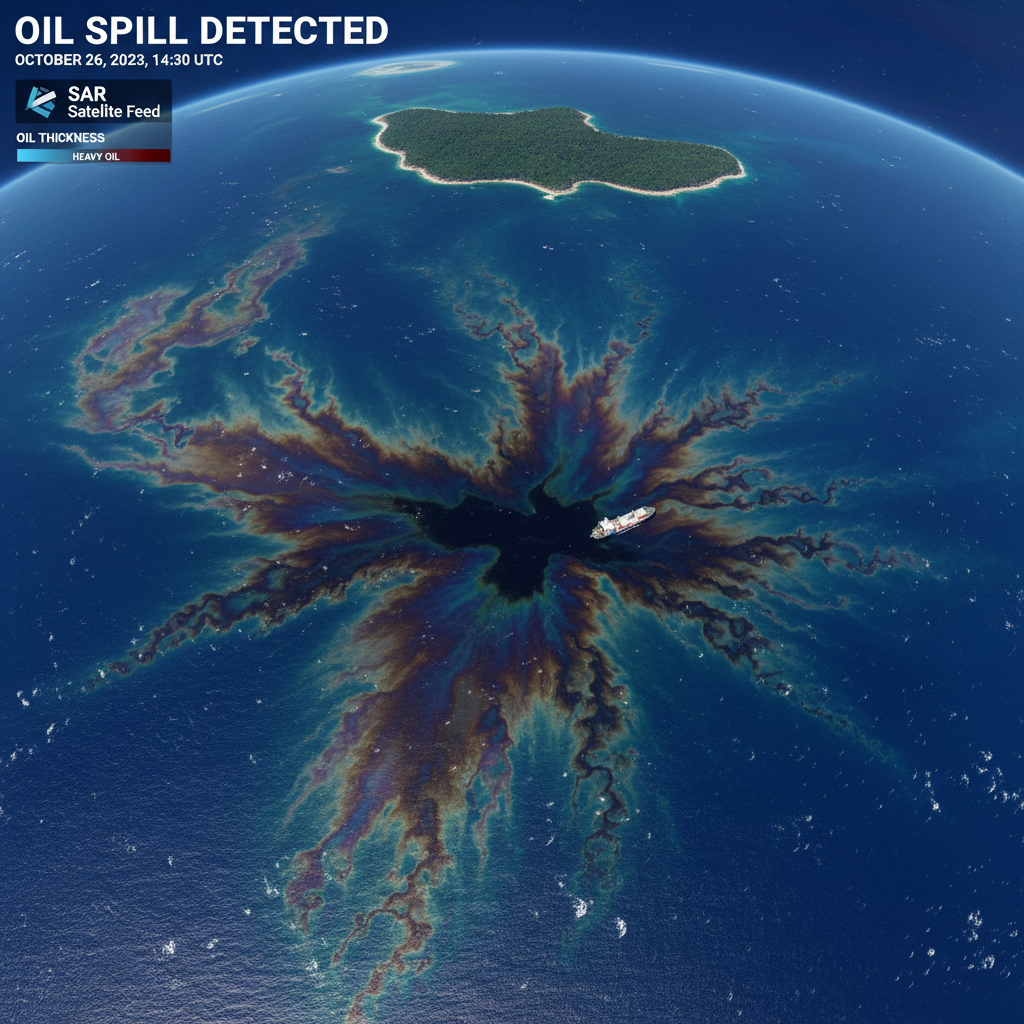

Traditional methods of monitoring oil separators often involve manual inspections and lab samples, which can be time-consuming and provide only a snapshot of the conditions at a specific moment. Real-time monitoring, on the other hand, offers continuous data, enabling operators to identify and respond to changes immediately. This proactive approach can prevent costly spills, reduce environmental impact, and improve overall operational efficiency.

Consider a scenario where a sudden surge in oil concentration enters the separator. Without real-time monitoring, this surge might go unnoticed until it’s too late, leading to a discharge of oily water into the environment. With Leakwise’s system in place, the increase in oil layer thickness would be detected instantly, triggering an alert and allowing operators to take corrective action before a spill occurs.

How Leakwise’s Technology Works

Leakwise’s floating sensors utilize Electromagnetic Energy Absorption to detect and measure the thickness of oil layers on the water surface. These sensors are designed to be highly sensitive to hydrocarbons while remaining unaffected by changes in water salinity, temperature, or the presence of other contaminants. The data collected by the sensors is transmitted wirelessly to a central monitoring station, where it can be visualized and analyzed. This information empowers operators to make informed decisions about process adjustments and maintenance activities.

One of the key benefits of Leakwise’s technology is its ability to provide early warning of potential issues. By continuously monitoring the oil layer, the system can detect even small changes that might indicate a problem with the separator’s performance. This allows for proactive maintenance and prevents minor issues from escalating into major problems.

Applications of Leakwise’s Technology

Leakwise’s real-time monitoring solutions are applicable across a wide range of industries, including:

- нефтеперерабатывающие заводы

- Нефтехимические заводы

- Сточные воды

- Нефтебазы

- Транспортные терминалы

In each of these applications, Leakwise’s technology helps to ensure that oil separators are operating at peak efficiency, minimizing the risk of environmental contamination and maximizing the recovery of valuable resources. Efficient Oil separator monitoring is key to environmental protection and operational efficiency.

Leakwise: A Legacy of Innovation

From its beginnings as Agar Technologies Ltd. to its current iteration as Agar Environmental Ltd., Leakwise has consistently demonstrated a commitment to innovation and environmental stewardship. The company’s long history, including periods under the ownership of Ionics Inc. and GE, has only strengthened its expertise and expanded its global reach.

Today, Leakwise continues to build on its legacy of success, providing cutting-edge solutions for real-time monitoring of oil separators and other environmental applications. With a focus on precision, reliability, and ease of use, Leakwise’s technology is helping organizations around the world to protect our environment and optimize their operations. Consider implementing an effective Oil skimmer control system for your operations.